VERY LOW WEIGHT

This system is very popular also thanks to its low weight. It is the lightest equipment of its kind available in the world. It weights only 1.2 kg – excluding the water bottle.

EASY ONE-HAND MANIPULATION

It is the simplest system from the user´s point of view. Thanks to its leight weight and easy manipulation the operator can handle it just using one hand.

The operator can carry the 1.2 kg US equipment DIO1000-2CH-RAIL suspended – using the straps – on his body. While leisure walking the operator holds the walking stick in one hand only and pushes it gently along the rail. He can easily operate it with his other hand.

DETAILED PROTOCOL

When a flaw is detected the equipment beeps. The operator steps back/walks back to detect the flaw in detail from different angles – see the description of the whole set – and to map the maximum of the recognized defect. When detecting the flaw the display automatically switches on to show the details. The operator´s left hand is loose to save the snaps of the defect. The software saves both the snap of the whole map of the defect, makes out an electronic protocol including the GPS description, localization and detailed information of the defect, the operator´s name as well as the date of the detection. If needed the operator can add other information e.g. hectometers. Data can be stored on USB.

DESCRIPTION OF THE WHOLE SET

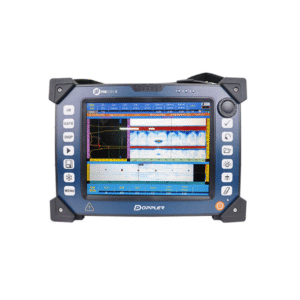

- DIO1000-2CH PORTABLE equipment – it includes of the equipment, a battery, a charger, straps for wearing

- Walking stick with a probe holder, an integrated probe, and a water bottle

- USB for data storing

- This particular system includes 3 probes while it is possible to apply a wide range of probes according to the customer´s needs and requirements. The probes are set in different agles to 70°,0° and -70°

ENERGY SOURCE

The batery – which is a part of the whole set – is rechargable in 220 / 240 V socket and lasts for about 10 hours.

WORK SAFETY

Work with the equipment is safe both for the operators and trains. It is thanks to its small size, low weight and easy handling.

Avis

Il n’y a pas encore d’avis.